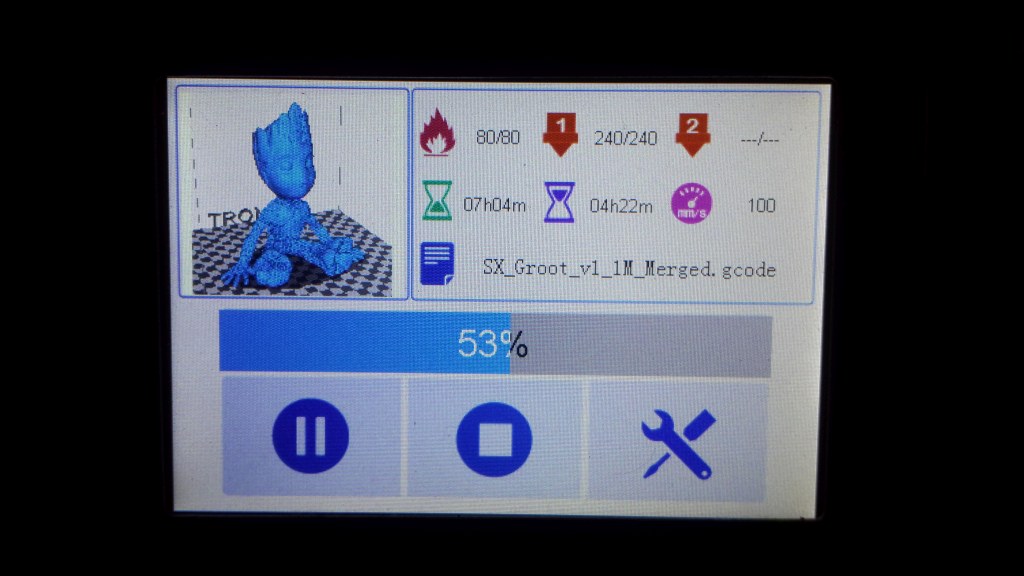

Greetings ! so this is what im up to today

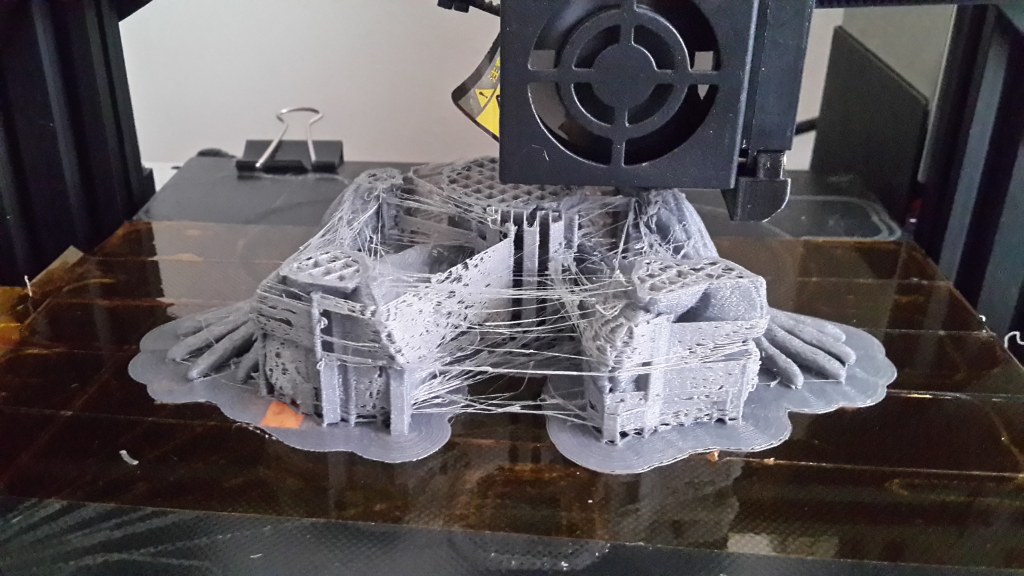

A bit messier than I would have expected.

thats what happens when u use free models, and thats actually minimal stringing by the supports compared to models ive printed using abs

a slower print would also be cleaner but im not going to wait 24 hours for something to print

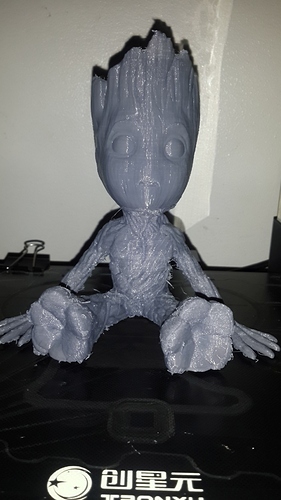

That turned out pretty good.

can be improved, i expected it to be a 12 hour print (cause thats what it estimated) and it ended up being a 16 hour print

What type of filament did you use?

Petg on my 2nd attempt, attempt 1 was abs which ended up warping halfway through, Abs sucks

You gotta keep ABS hot the whole print. Having an enclosure is almost necessary for big prints in ABS

thats what iv’e noticed, not even the kapton tape helped to keep the abs sticking to the bed. im just stuck with 3 rolls of abs that i need to use up

What’s your built plate made of? If you mix some ABS in acetone, and make a slurry, you can wipe a thin layer on the plate while it’s cool, then the extruded plastic will stick.

glass bed

i suspect if it was a 24v bed that could reach 100 degrees the abs would stick better but my bed is only 12v so it maxes out at 85 degrees

Oh dang. 12v is enough for an aluminum bed to reach 100. Don’t know about glass…

i can manually enter a 100 but it never gets to it, just tops out at 85 everytime

His 3D printer only arrived during lockdown…

I did a bunch of reading up on them a few years back when I was considering building one. Don’t know anything about PETG plastics or anything else use these days though. I didn’t bother keeping current.

Haha it was worth a try.